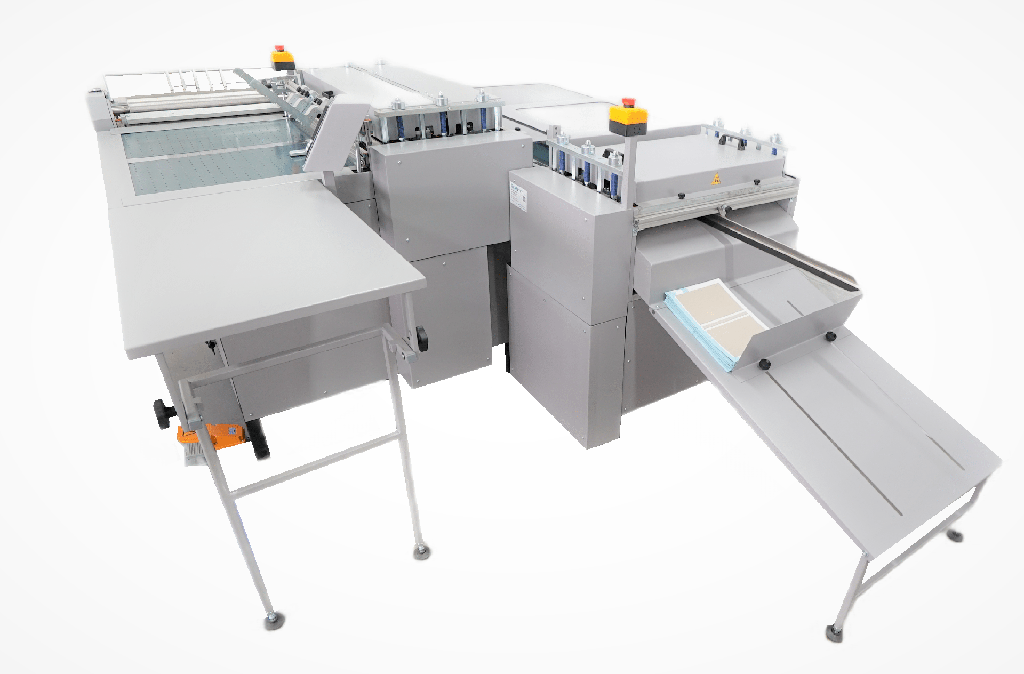

Casemaker Pro + pressing module 4 sides Grafcut GC-480 Pro 4

GC-480 PRO 4 is a casemaker dedicated to produce hard cover cases. The machine closes all 4 case sides and corners in one pass thanks to two turning in modules. The air is all pressed out during the process.

The glue application unit is used to cover flat surfaces such as paper, leather, PVC with a thin layer of glue. The machine is able to use hot glues, which allows the use of organic adhesives of animal origin, eliminating the risk of cover waving due to the large amount of water in the glue – not requiring a long pressing time of the finished cover, reducing the time needed to clean the machine to an absolute minimum. The offered machine is a simple control, large and durable rollers made of stainless steel, standard equipped with preheating to prevent water condensation on the sheet and water supply from the tank activated by pressing a button. All this makes the work as easy as possible and eliminates many potential problems occurring when operating similar devices.

Casemaking table allows you to work on a variety of materials with different properties. It has centre LED backlight for positioning and motorized conveyor belt with suction that moves in and out the case. The turning in module does not require an air supply and works mechanically, very quietly in comparison to other devices on the market.

Gluing unit features:

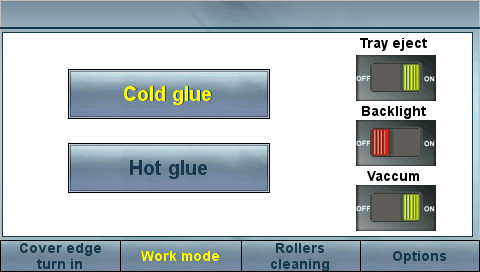

can be used with cold glue or hot glue (recommended extra glue tank if using both, machines comes with one tank)

2 stainless steel, big diameters rollers (acid resistant) for better glue application

Electric heater, metal tray with glue disposed into water tank heated by the heater.

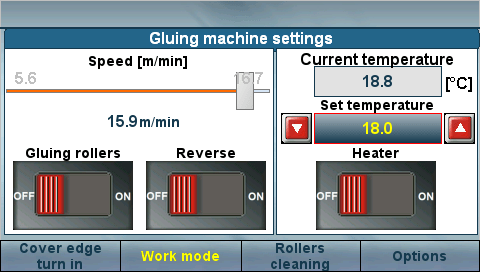

Rollers speed fluent adjustment from panel

Preheating bar before metal rollers (prevents water collection on table) in standard

Water tank with pump for adding water to glue tank by pressing button on panel

In standard version made for application of glue for material from 80 gsm to 250 gsm (with optional rigid board module up to 5mm material thickness)

Cleaning time after job about 5 minutes

Casemaker features:

Colour touch screen for settings and diagnostics

Motorized rollers for edge turning in and pressing the case, does not require any compressor. Silent operation.

Motorized, vacuum table (pump included) for moving the case in and out

Possibility to do pressing only or turning in and pressing.

LED cover central backlight from bottom

Board positioner operated by hand

Foot pedal for board stoppers

Top shelf for boards and covers

OPERATION:

The operator manually feeds the cover to the gluing machine where the glue is automatically applied

The cover sheet smeared with glue is placed by operator it on the table, then manually adds grey boards and a spine board.

The operator presses the pedal and case is moved into turning in module. First section closes 2 edges, next corners are closed. Case drops into motorized conveyor belt that pushes it into second turning in section closing next 2 edges. Covers that leave the machine are immediately usable. During the turning in operation, the cover is pressed through a system of guide rollers removing the air.

Technical info

Max rollers speed 5,6- 16 m/min

Max paper width (mm) 520 mm (glue application only)

Material thickness** gluing only :80-300 gsm or up to 5mm (with optional rigid boards module) turning in: 80-250 gsm

Heating time ~15 min

Temperature (°C) 0-95 degrees (possible to work with cold glue with 0 degrees temperature ex. when making inner paper)

Glue tank capacity 4l

Glue type*** Organic glue (*** possible to work with cold glue with 0 degrees temperature ex. when making inner paper)

Productivity* ~ 240-300 pcs/ hour

Cover material type Paper, textile, laminated paper, photopaper, eco leather, pvc, polyurethane

Min size of open case 145 x 145 mm

Max size of open case 480 x 770 mm - edge turn in 20mm

Board thickness** 1,5 mm- 4 mm

Spine width 1-100mm

The minimum distance between boards when producing covers without a spine 4 mm

Overlap covering material adjustable in range 10-20 mm

Vacuum on table YES (integrated air blower)

Power supply 3 Ph, 400V/50Hz

Power installed 3,8 kW (heater switched on); 0,8 kW (heater switched off).

Dimensions 299cm x 194 x 117 cm - min door width. 135cm

Weight (kg) 900 kg

Air compressor Not required

NOTE! * depends on the type of material and operator skills ** tested values. Out-of-range materials must be checked prior to purchase. *** it is also possible to use cold glue, e.g. in the case of pasting the inside end paper under a binder